Fabric always comes first

How Auralee's Ryota Iwai makes clothes

Today’s post is brought to you by Blackbird Spyplane’s Classified Tier Subscribers, who make this independent reader-powered miracle possible — upgrade your subscription if you haven’t already, and enjoy a better life in the Spyplane Inner Sanctum.

Our interviews with Nathan Fielder, Brendan from Turnstile, Adam Sandler, Issy Wood, MJ Lenderman, Evan Kinori, Steven Yeun, Maya Hawke, Bon Iver, André 3000, Sandy Liang, Eckhaus Latta, Matty Matheson, Laraaji, Eckhaus Latta, Tyler, The Creator, John C. Reilly, Rashida Jones, Jockum from Our Legacy, Father John Misty, Kate Berlant, Camiel Fortgens, Clairo, Conner O’Malley and more are here.

Check out our monumental new list of the 50 Slappiest Shops across the Spyplane Universe.

Auralee is one of the world’s greatest independent lines. I (Jonah) first saw their clothes in person in the fall of 2021 at C’H’C’M’, in New York, where I bought an oversize tan sweater in a loose-gauge kid mohair that floated around me like a cloud. Auralee’s specialty back then was knitwear, but these days it’s hard to name anything they don’t do well. They’ve become known, at this point, not for any one category of garment, but for their elaborate materials development, their fantastic sense of color and, in collaboration with the stylist Charlotte Collet, their sauced-out runway layering.

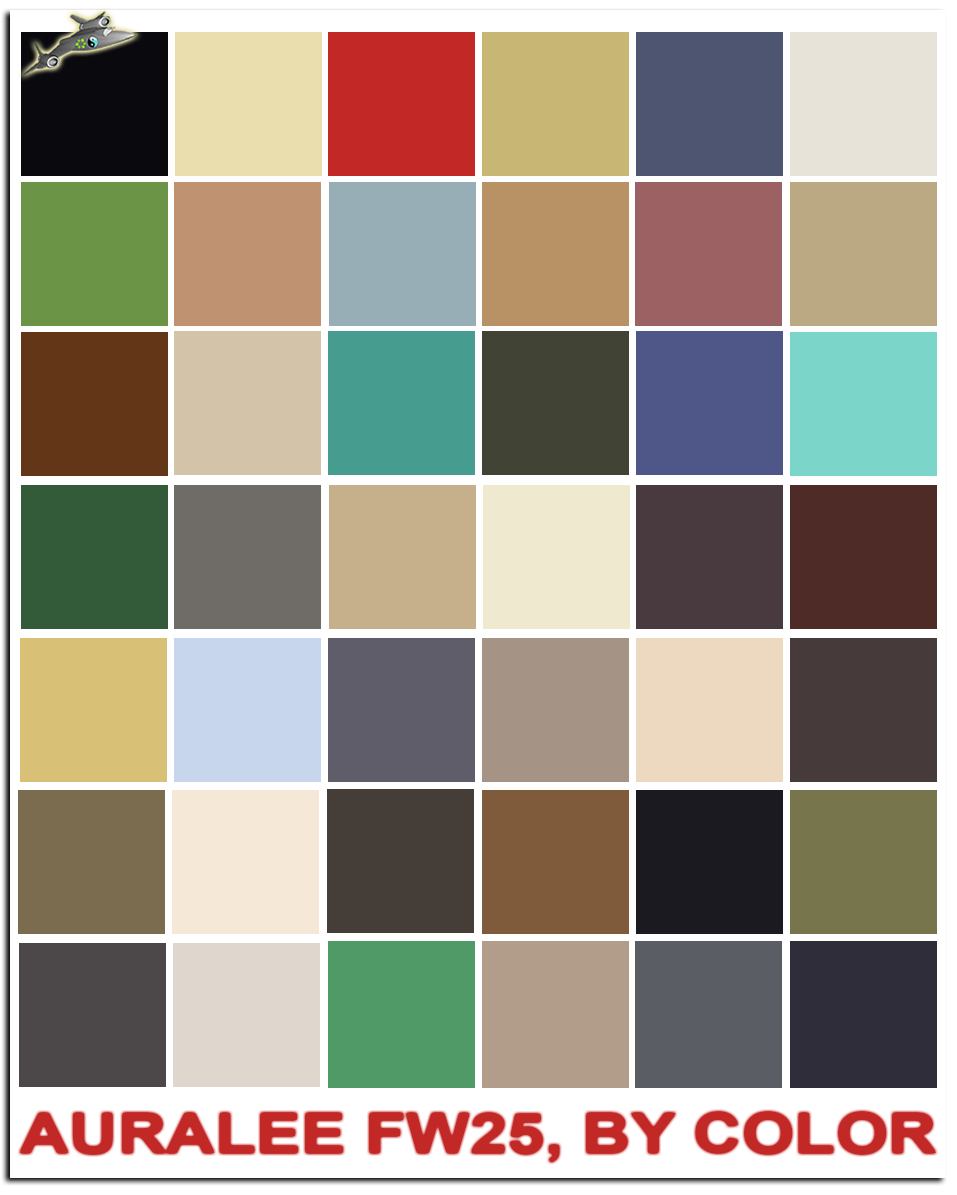

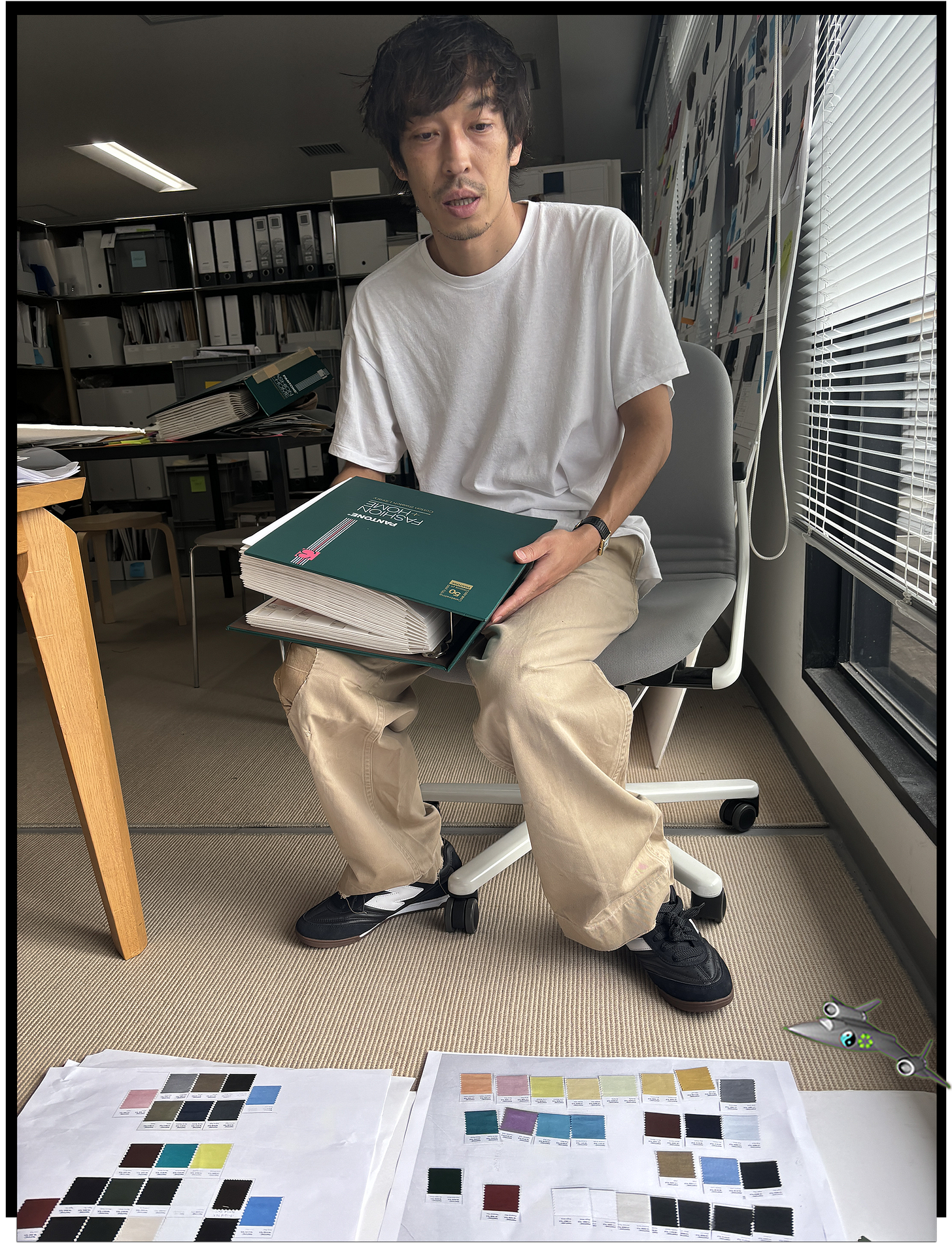

Overseeing it all is Ryota Iwai, Auralee’s soft-spoken designer. Erin and I met Ryota this past spring at Auralee’s Tokyo HQ, where he was in the thick of work on the Spring 2026 collection. He told us he’d just been standing in front of hundreds of Pantone chips, pushing them around like puzzle pieces. As we put it in our Spyplane Ultimate Tokyo Travel Guide: “Other designers might work from a set of clear references — the costumes in a favorite movie, say, or the flora of a beloved landscape — but not Ryota, who chooses colors by looking at colors, following the chromatic vibrations where they lead him.”

The other day, I called up Ryota for a conversation about how he makes clothes. Color came up a little. But the main topic was fabric itself. I’ve heard a lot about his obsession with materials development over the years. For him, it’s at the core of what Auralee does, and it explains why his clothes fit, drape, look and move the way they do.

“With any fabric,” he told me, “no matter how great the raw material may be, if it’s simply knitted or woven as-is, it won’t become the kind of textile we’re aiming for. For us, good raw materials are just the starting point. We almost never use them without further refinement.”

I wanted to know more about what that actually meant. The result was a fascinating, extremely fabric-focused Blackbird Spyplane Interview with one of the dopest designers working.

Blackbird Spyplane: I’m always curious to hear about the things people love to collect. Are you a collector?

Ryota Iwai: “In Japan there’s a big collector mentality — you look at a place like Nigo’s house, and it’s full of toys and other things. For me, though, it’s not really the case. I don’t buy a lot of things. The bike I ride to work every day, I’ve been riding it for 20 years. And the things I do collect all tend to relate to work, whether that’s vintage pieces, reference pieces, or reference fabrics. Those are the only things I spend time digging for. And whereas a lot of collectors specialize in all one thing — all Levi’s, all American vintage, all military — I don’t have such strict barriers. For me, it could be military, European tailoring, American designers from the ‘40s all the way to the ‘90s. It’s not stuck in just one category.”

Blackbird Spyplane: If we can break down design into 3 rough sets of decisions — decisions about fabric, decisions about color, and decisions about shape — do you always prefer starting with one, then figuring out the others? Or does it change from piece to piece?

Ryota Iwai: “I really only have one option, because the fabric-design process is what takes the most amount of time. Unlike a lot of other brands, that’s our main focus. So it’s inspiration and figuring out what to do with fabric, then developing and testing it. Fabric always comes first. Then comes color, then comes shape.”

Blackbird Spyplane: What percentage of Auralee fabrics is custom-developed at this point?

Ryota Iwai: “I was going to say, ‘Everything besides the leather is custom,’ but this season, even with leather, the color and treatments were all customized. So as of this collection it’s 100%.”

Blackbird Spyplane: I know you do a lot of the materials development in-house. Are you enlisting scientists and labs to help you experiment, too? How deep into the molecules are we talking?

Ryota Iwai: “No, it’s not scientists and laboratories. But not everything is done in-house. One thing we’re lucky to have in Japan is a large network across the country of specific factories and places that specialize in certain things. Certain areas are better or more experienced at doing things. So the same way you hear people talk about Okayama denim, there are areas that specialize in silk, areas that specialize in wool, and so on, across the board. We develop our fabrics in collaboration with those specialists.”

Blackbird Spyplane: The past several seasons you’ve made a bunch of pieces in a very sick bright red. Next spring you’ve got a bright yellow coming. I know Auralee is after a kind of refinement, so when you’re working with primary colors like those, I wonder how you make sure they’re not too loud. How do you temper a big red or yellow so it doesn’t clash with the more-muted colors that tend to dominate in your palettes? Like, is there a specific ratio of gray you like to add to the primary, or some other technical formula along those lines?

Ryota Iwai: “I’m happy to hear you like those colors, because when it comes to our brand, and our color theory, I always want things to feel wearable. But there’s no set formula. The only way we can achieve it is by testing: testing dyes, making samples, and making more samples until the color feels right. And especially for a red or a yellow, that back-and-forth can be quite a long process.”

Blackbird Spyplane: Because of the time and the cost, the extensive materials development you’re talking about is something we tend to associate with bigger brands. How do you do it on an independent level?

Ryota Iwai: “I do think it’s rare for an independent brand. But it’s the foundation of what we do, and it started with a naive part of my approach: Early on, I would go to factories, meet people, explain what I wanted to do, and in the back of my mind I was worried we might be too small to meet their minimums, but thankfully I ignored that, because forming those relationships early on is the only reason it’s been able to work.”

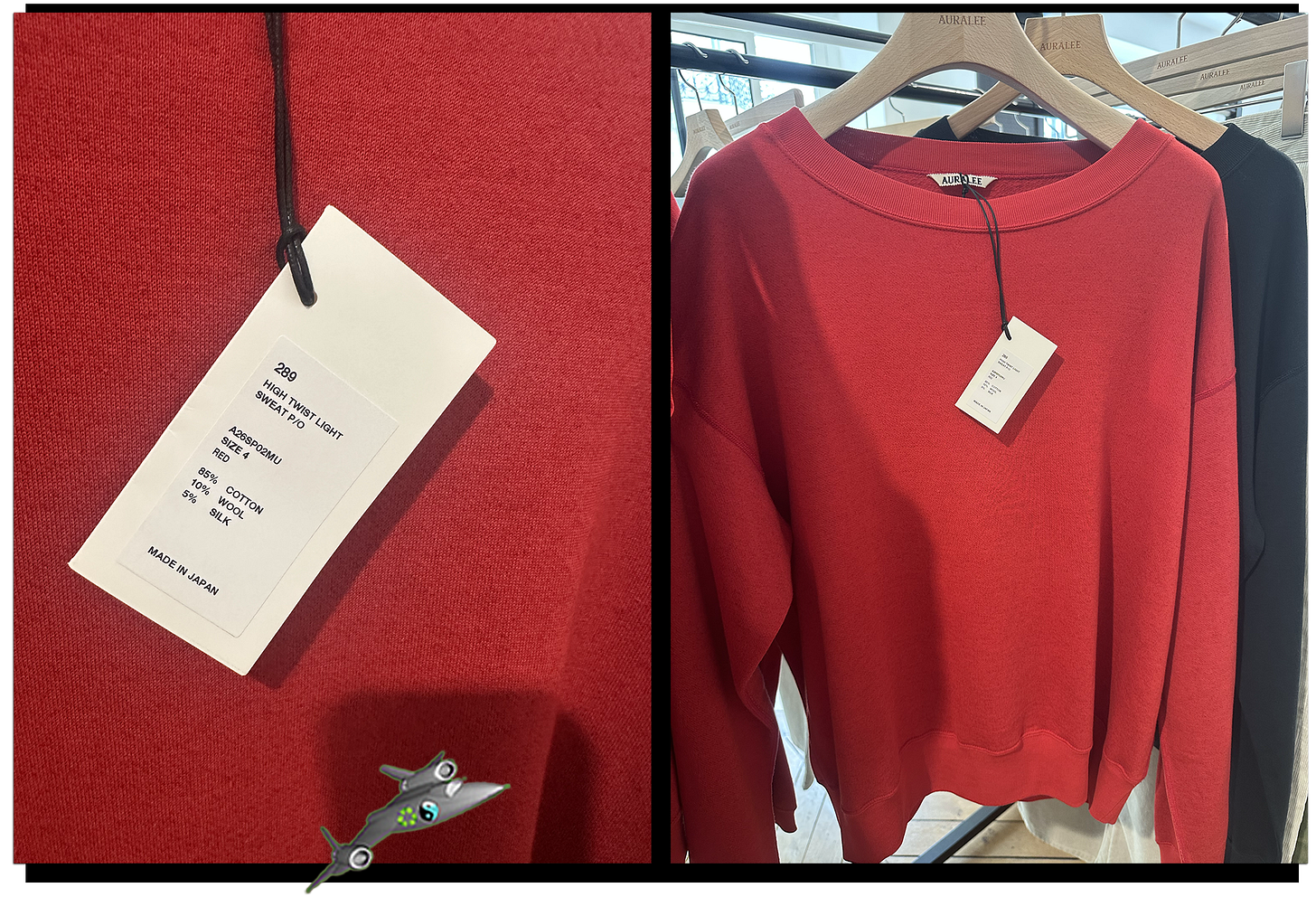

Blackbird Spyplane: You do something cool I wanted to ask about: You engineer natural fibers to replicate the look, feel and performance of synthetics. Auralee’s wool canvas is dense, water repellent, and just so technical-looking that someone might mistake it for a nylon. Or, I saw these sweatshirts you’ve got coming next spring, where you got the outsides to feel exactly like an old 50/50 cotton-poly blend, except it’s made from cotton, wool and silk. Tell me about your interest in developing these sorts of natural mock-synthetics…

Ryota Iwai: “We incorporate some synthetics in our clothes, but the minimums that go with them tend to be larger, and I also just prefer to use natural fabric. But I’m not against synthetics, at all. I own an old cotton-poly sweatshirt that inspired the pieces you’re talking about, and it’s one of my favorites. As to why I do this, I like playing with the idea of familiarity, where you have this thing that reminds you of something else you’ve seen before, but how do we do it in an way that’s original? There’s a fleece we made for autumn that’s all silk. It looks familiar, but there’s a unique method of making it. I like to play with those expectations, between familiarity and originality.”

Blackbird Spyplane: I see that same kind of play across Auralee’s designs, generally, not just the fabrics.

Ryota Iwai: “Yes, it’s the same when it comes to the shapes. It’s about sampling something pre-existing, and tweaking it, to make something that’s original, but familiar.”

We asked Ryota to geek out on the development of 4 Auralee fabrics:

Wool Max Canvas, woven tight and baked in a kiln:

“Canvas is usually made with thick, coarse yarns, for a rough texture and a strong, durable fabric,” Ryota explains. “For this canvas, though, we used fine Super 120s wool. By weaving it at a very high density, the fabric has a crisp, structured drape. It feels light but holds its shape. And thanks to the fineness of the fibers, the weave is uniform and clean, giving the fabric a refined appearance” — almost technical, if you ask us. Auralee then presses the fabric in a “large kiln, like a pressure cooker,” in a process they liken to ironing. “It also has water-repellent functionality” thanks to a coating applied at the end.

Cotton Flat Yarn Rib Knit, coated in the starch of an Asian root vegetable:

Auralee has been making this fabric in slightly varied forms since SS17. “I set out to make a cotton knit that could be worn casually even in summer,” Ryota says. “Summers here are pretty brutal, super wet and hot, and the natural feeling of cotton isn’t necessarily best suited for that.” He found success “with a konjac treatment, where the fabric is coated with a starch derived from the konjac plant” — a tuber-like root vegetable native to Asia. “It has a history in Japanese fabric-making, it’s a traditional process for making things more wearable for summer.” The result is “a smooth surface with a subtle unevenness, and a dry touch. It almost gives it the feel of a linen.”

Finx Twill cotton, hardened, washed and reversed:

Finx cotton is an extra-long-staple Egyptian cotton. To create this specific twill fabric, Auralee weaves Finx yarn “at a high density,” Ryota explains. “After the fabric’s woven, we apply a dye process to harden it. Then we wash it twice. Washing slightly damages the fabric, making it more comfortable, and the raw material is so good there’s no real deterioration. The washing also gives the colors a subtle, lived-in look.” Finally, “with twill, the inside is smoother, while the front has a slight texture. We reverse the fabric, so that the side that would normally face inside becomes the outer surface. Placing the textured side against the skin creates a unique, airy feel. And I like that the side with a more subdued luster becomes the outer surface.”

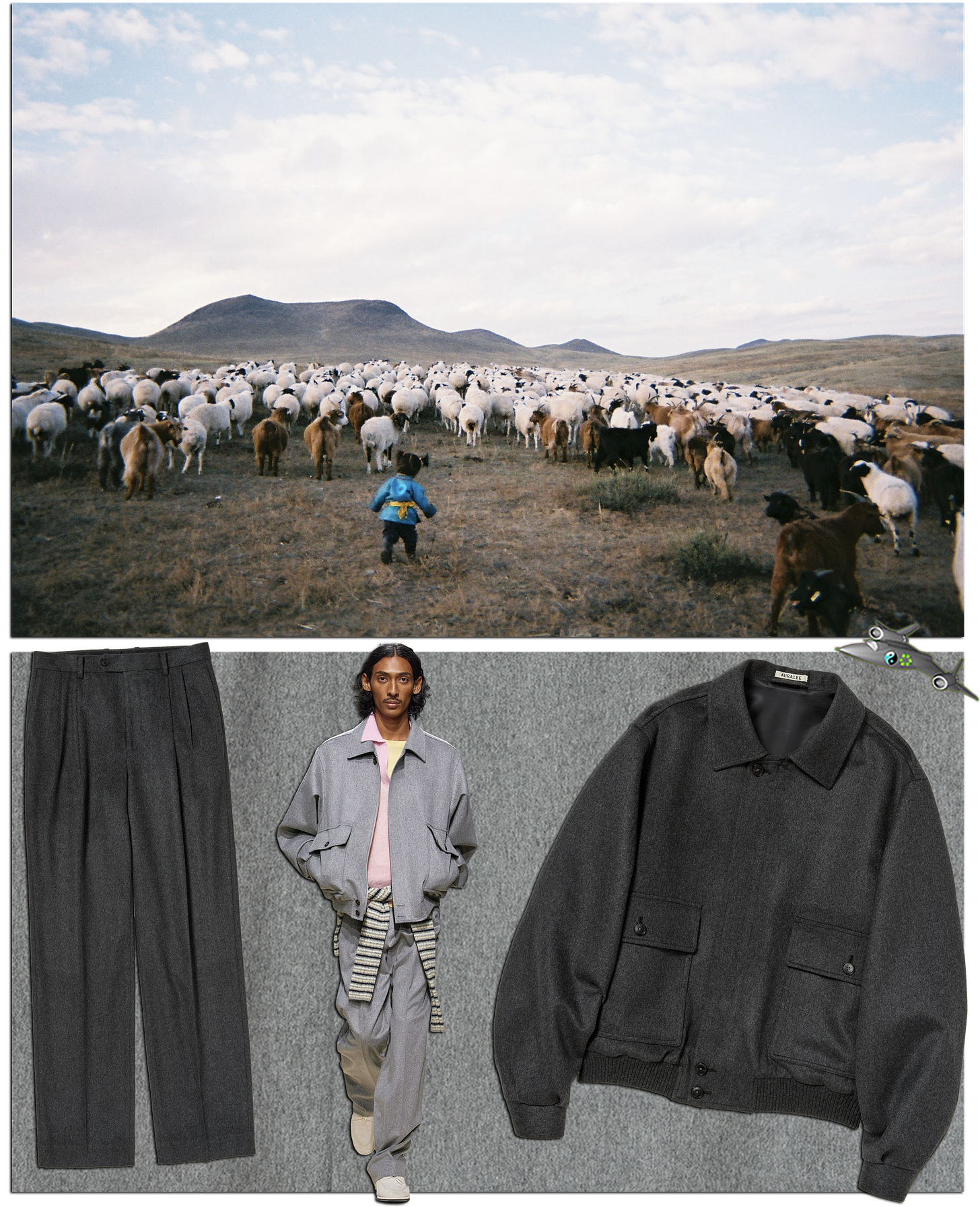

Cashmere Moleskin, gently combed off Mongolian goats, then woven, brushed and buzz-cut:

“In Mongolia, traditional nomadic herding is still very much alive,” Ryota says. “I’m drawn to how traditionally and naturally the cashmere goats are raised, free from chemical management, surrounded by vast open landscapes. The goats live in a harmony with the nomadic people, and they aren’t shorn to collect their fibers: They’re gently combed. We make 100% pure cashmere moleskin from these goats. As a raw material, cashmere carries a glossy luster, but for everyday wear, I prefer a finish that feels more understated. So we give it a calmer, more matte look by brushing it, then cutting it to its limits. Almost like a buzz cut.”

Classified-Tier Spyfriends request, share and receive Mach 3+ recommendations in our SpyTalk Chat Room.

Man has me out here looking into the feasibility of raising a cashmere goat herd. Great read.

Thanks for this. Great to read such an in-depth interview in English with one of my favorite designers of the day. And so awesome to know the details behind some of these fabrics. I’ll read the fabrics’ descriptions online sometimes, but love how he gets into the process here — it really gives a sense of the humans (and animals!) behind, and the labor that goes into, all these great pieces.